|

Common Uses: The Kansai Special

PMD waistband machine is a specialized sewing machine that is designed for the

production of waistbands for various types of garments. Here are some of the

uses of the Kansai Special PMD waistband machine in the apparel manufacturing

industry:

- Elastic Waistbands: The PMD waistband

machine is often used for attaching elastic to the waistband of garments, such

as shorts, pants, skirts, and underwear. It can produce a strong and secure

attachment, ensuring that the garment stays in place during wear.

- Straight Waistbands: The PMD waistband

machine can also be used for creating straight waistbands on pants, skirts, and

shorts. It can produce a neat and professional-looking finish, which is

essential for high-quality garments.

- Curved Waistbands: The PMD waistband

machine is capable of creating curved waistbands for garments, such as jeans

and trousers. This requires a specialized technique, and the PMD waistband

machine is designed to handle the unique requirements of curved waistbands.

- Belt Loops: The PMD waistband machine is also used

for attaching belt loops to the waistband of garments. Belt loops are essential

for providing the wearer with the option to wear a belt, which is often

necessary for workwear and other heavy-duty garments.

- Decorative Stitching: The PMD waistband

machine is capable of producing a wide range of decorative stitches, which can

be used to add a unique touch to waistbands. This is especially useful for

high-end fashion garments, where attention to detail is crucial.

In summary, the Kansai Special PMD waistband machine

is an essential tool in the apparel manufacturing industry. Its ability to

handle a wide range of waistband styles and produce high-quality results makes

it a popular choice among manufacturers.

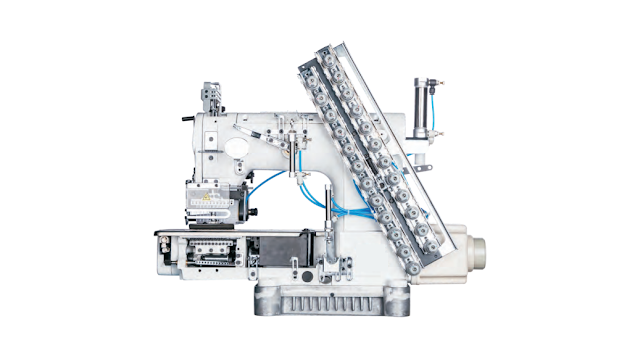

Components: The general features

of the Kansai Special PMD waistband machine. The Kansai Special PMD waistband

machine is a specialized sewing machine that is designed to attach waistbands

to various types of garments. The machine features a flatbed table with a

needle plate, which supports the fabric during the sewing process.

The machine has a unique design that allows it to

handle the complex curves of waistbands. It features a specially designed

folder, which folds the fabric as it passes through the machine. The folder can

be adjusted to create different waistband shapes, such as straight or curved.

The machine also has a feeding mechanism that can

handle heavy-duty fabrics, such as denim and canvas. The feeding mechanism

consists of upper and lower feed dogs, which work together to move the fabric

through the machine at a consistent speed.

The Kansai Special PMD waistband machine is capable

of producing a wide range of stitches, including straight, zigzag, and chain

stitches. It can also produce decorative stitches, such as scallop and picot

stitches, which can add a unique touch to waistbands.

In addition, the machine is equipped with an

automatic thread trimming system, which cuts the thread at the end of each

seam. This helps to speed up the sewing process and ensure consistent thread

lengths.

Overall, the Kansai Special PMD waistband machine is

a versatile and essential tool in the apparel manufacturing industry. Its

unique design and features make it an ideal choice for attaching waistbands to

a wide range of garments.

Problems and Solutions: Like any machine, the

Kansai Special PMD waistband machine may experience problems from time to time.

Here are some common problems and solutions in the apparel manufacturing

industry:

- Skipping Stitches: One common problem

with the PMD waistband machine is skipping stitches. This can be caused by a

dull needle, incorrect thread tension, or improperly adjusted feed dogs. To

solve this problem, operators should check the needle and replace it if necessary,

adjust the thread tension, and ensure that the feed dogs are properly adjusted.

- Puckering: Puckering is another common problem

that can occur when using the PMD waistband machine. This is often caused by

incorrect thread tension or feeding, or by using the wrong type of fabric. To

solve this problem, operators should adjust the thread tension and feeding, and

ensure that the machine is set up for the specific type of fabric being used.

- Fabric Jamming: Fabric jamming can occur when the

fabric becomes stuck in the machine. This can be caused by a number of factors,

including incorrect threading, incorrect needle size, or a buildup of lint in

the machine. To solve this problem, operators should ensure that the machine is

properly threaded, use the correct needle size, and regularly clean and

maintain the machine.

- Machine Vibrations: Machine vibrations

can occur when the machine is not properly balanced or when the feed dogs are

not properly adjusted. This can lead to uneven seams and other problems. To solve

this problem, operators should ensure that the machine is properly balanced and

that the feed dogs are properly adjusted.

- Thread Breakage: Thread breakage can

be caused by a number of factors, including incorrect thread tension, a dull

needle, or using the wrong type of thread. To solve this problem, operators

should adjust the thread tension, replace the needle if necessary, and use the

correct type of thread.

In summary, the Kansai Special PMD waistband machine

is a reliable and high-quality machine that is widely used in the apparel

manufacturing industry. However, like any machine, it may experience problems

from time to time. By following best practices for machine maintenance and

troubleshooting common problems, operators can ensure that the machine operates

smoothly and efficiently.

Hot Searches.

1. Buy Industrial Auto Sewing Machine.

2. Auxiliary Machine Ready Stock available for sale.

3. Sewing Machine Layout for your garments factory.

4. Denim Bottom Automation.

5. Shirt Sewing Machine Automation.

Post a Comment